Brennan Timber Frame Day 4

The main bent of the frame is pegged in place after its final fitting. The side headers and their joinery will have their final fitting tomorrow. Visually, the frame will really begin to come alive when radius curves are cut into the braces. Right now, the whole frame feels too bulky and masculine, but cutting those radiuses will strike a pleasing balance between strength and grace.

Always enjoy hearing the pitch change as the pegs find their way home. The tenon's peg holes are drilled out slightly off center by 1/8" to create a solid connection that cinches tightly together. As the peg is hammered through, the carefully marked offset pulls the brace into the other timber. Note that this frame consists of Western Red Cedar timbers, and as such provides adequate amounts of "crush factor" that allows for this sort of offsetting. Working with wood requires a relationship with the material. Laying out an offset on a cedar brace may not work well at all in another species such as oak.

This set of four braces is all a part of the main front bent. Here they are all stacked and completed together. For any serious build, especially a production build, it is essential to keep everything organized. Keep like with like. Organize the materials, tools, processes, motions, and conversations in such a way that the work becomes a dance.

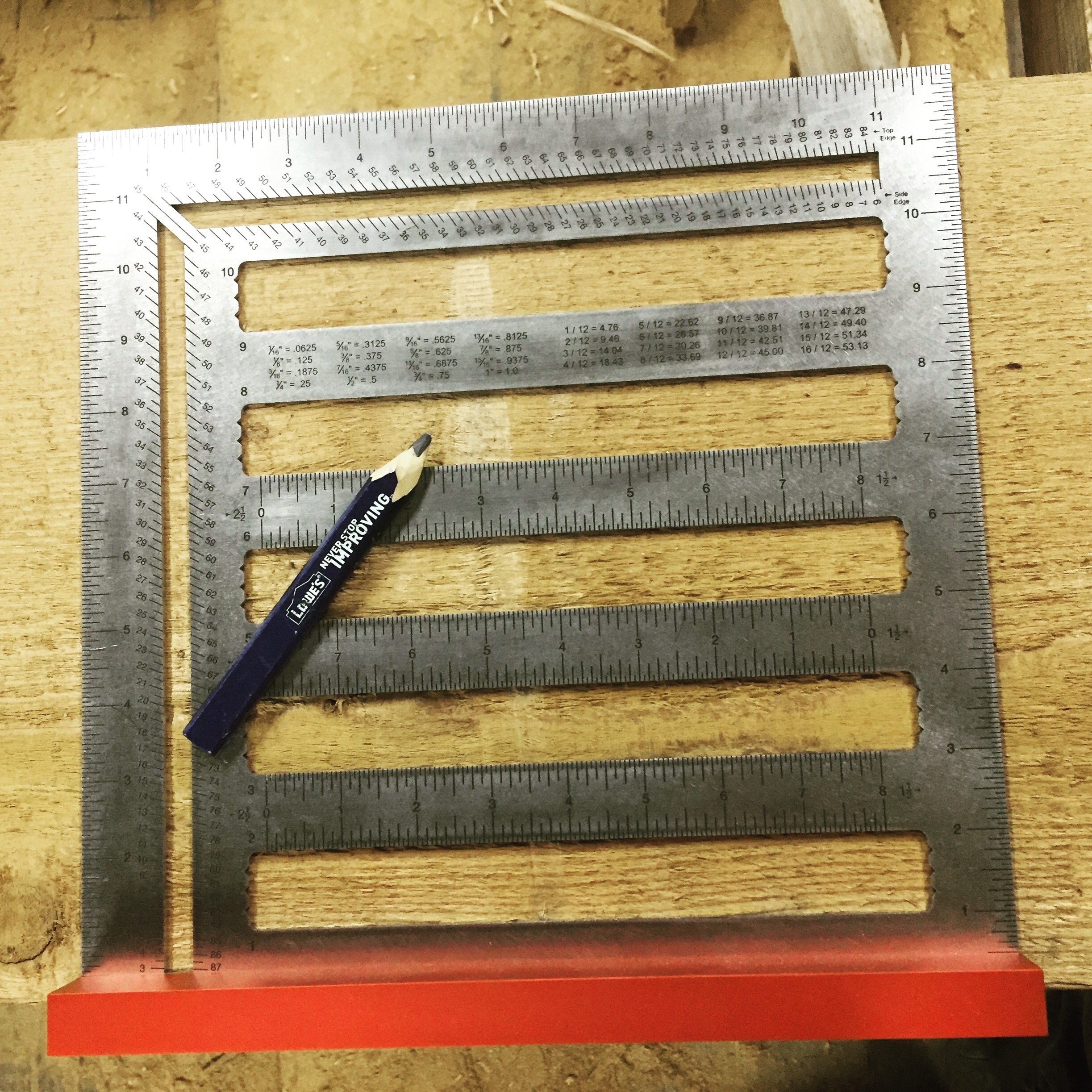

For several years, I've used an original AL layout tool to map out my mortises, tenons, and general joint work. This is the first job that I have used a more detailed iteration from the folks at Timber Frame HQ. I quite like the overall design and the display of measurements. It's a handy tool that conveys dimensional information quickly and accurately.